Robotic System for Chemical Experiment Automation with Dual Demonstration of End-effector and Jig Operations

Hikaru Sasaki, Naoto Komeno, Takumi Hachimine, Kei Takahashi, Yu-ya Ohnishi, Tetsunori Sugawara, Araki Wakiuchi, Miho Hatanaka, Tomoyuki Miyao, Hiroharu Ajiro, Mikiya Fujii, and Takamitsu Matsubara

[arXiv]Abstact

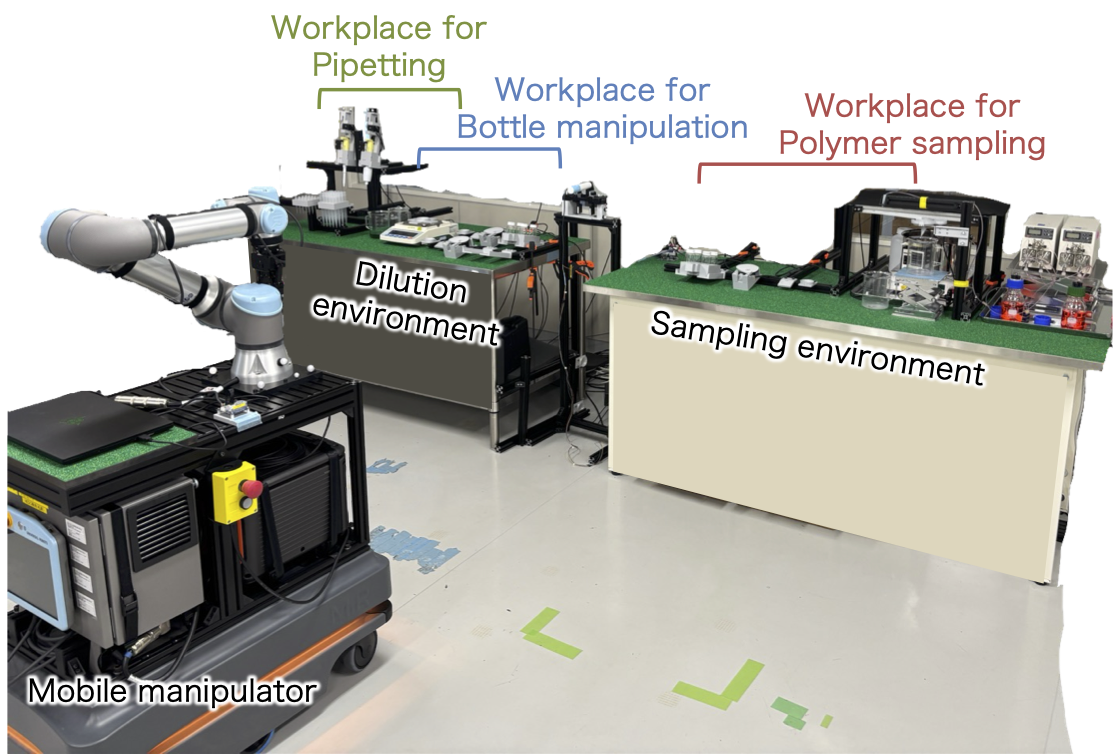

Overview

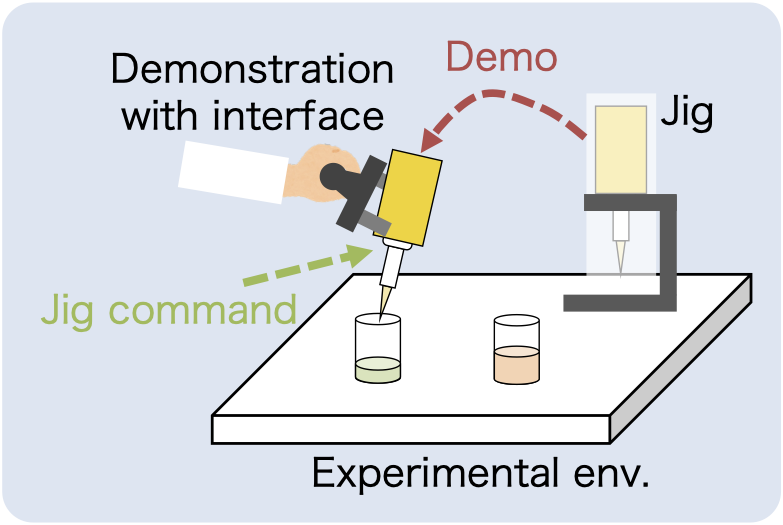

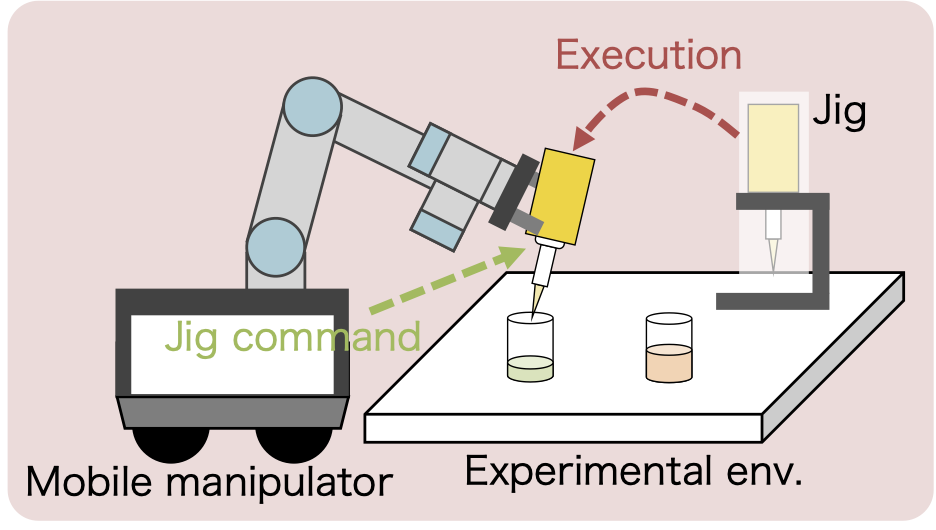

This paper proposes a dual demonstration-based robotic system for automating chemical experiments. Instead of manually programming robot motions and jig operations, chemists demonstrate the actions using an intuitive interface and jig controller. The robot then reproduces the task precisely, streamlining automation for complex lab workflows. Concept of dual demonstration: (a) chemist demonstrates using the interface and jigs, (b) robot executes the task.

System Architecture

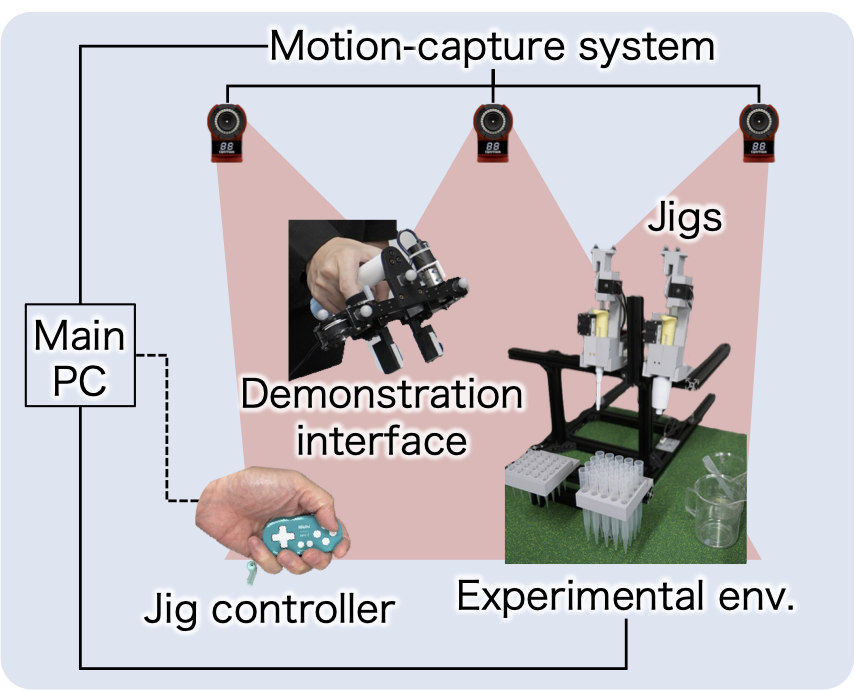

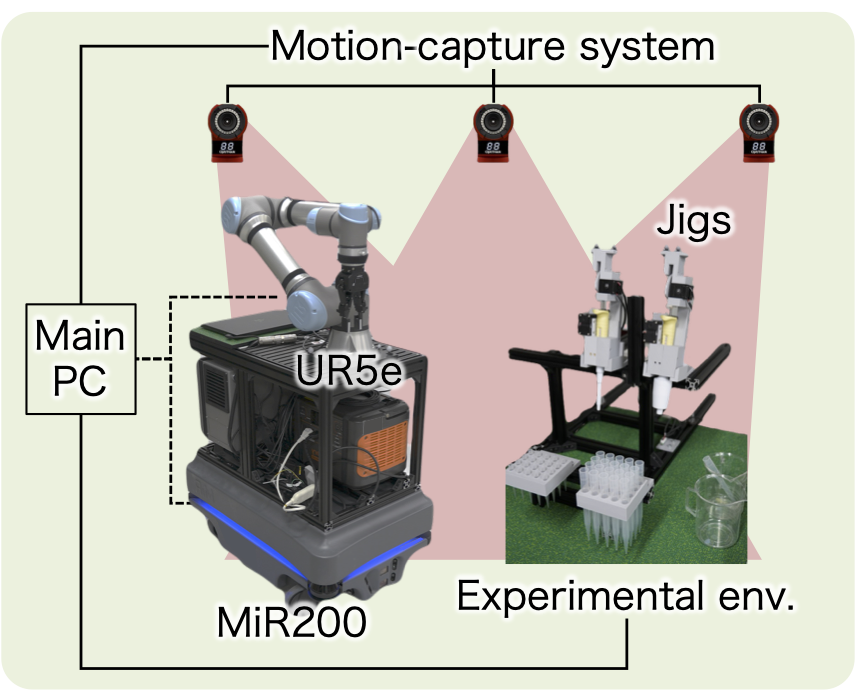

The developed system integrates four main components:

- A motion-demonstration interface that mimics the robot’s gripper

- Specialized experimental jigs for tasks such as pipetting and bottle handling

- A mobile manipulator (UR5e on MiR200)

- A motion-capture system for recording demonstrations The demonstration phase and execution phase are connected through a time-synchronized data logging and control pipeline. System overview is shown in Fig. 4.

Experiments

Settings

To validate the system, a simulated polymer synthesis workflow was designed. It consisted of three workspaces:

- Polymer sampling

- Bottle manipulation for dilution

- Pipetting operation

To evaluate the proposed dual demonstration system, we conducted a full-cycle experiment simulating a polymer synthesis workflow. In each task, a chemsit demonstrated a motion once and then the motions are autonomously executed by the mobile manipulator. Experimental environment layout with three workstations (Fig. 18).

Results

The robot performed all actions based on a single human demonstration, including bottle manipulation, polymer sampling, and dilution. The results confirm the system’s precision, synchronization, and reliability across complex, multi-step tasks.

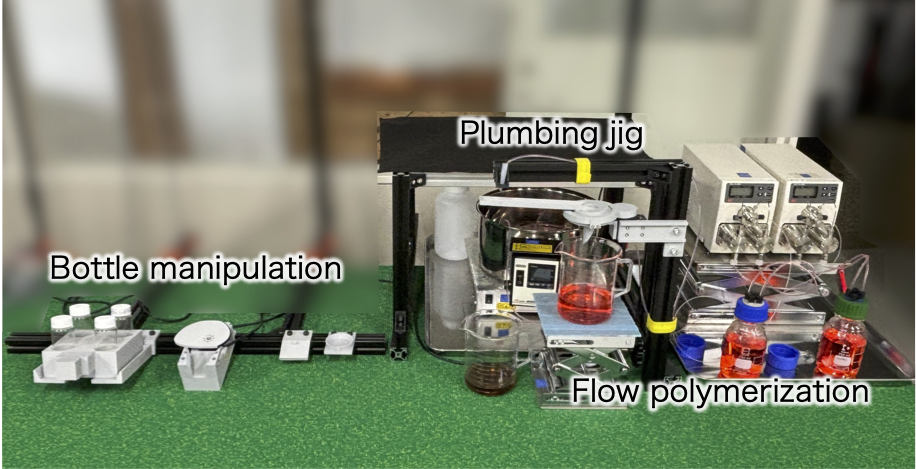

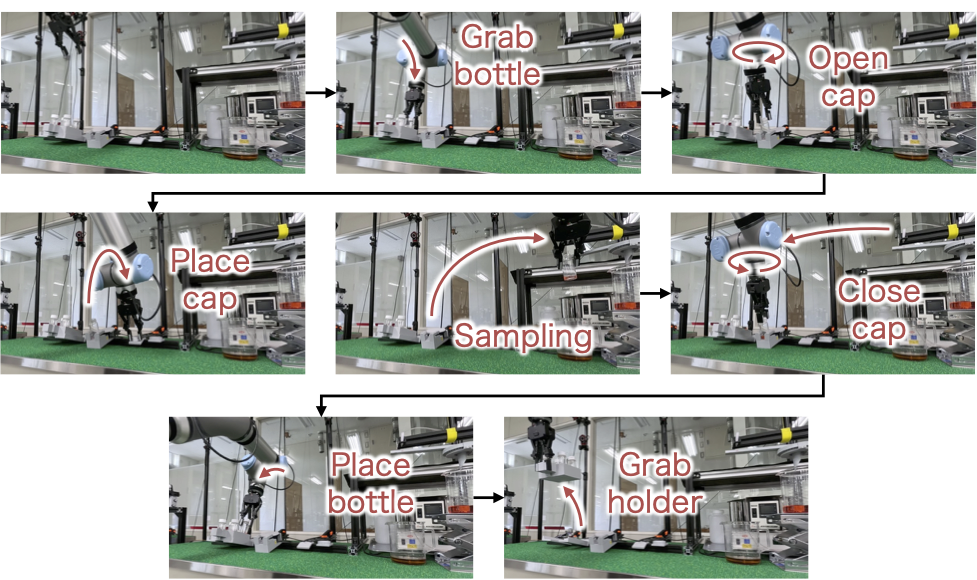

Task 1: Polymer Sampling

At Workspace 1, the robot:

- Retrieves a bottle from the case

- Opens the cap

- Samples polymer (colored water)

- Closes the cap and returns the bottle

Robot-executed actions for polymer sampling.

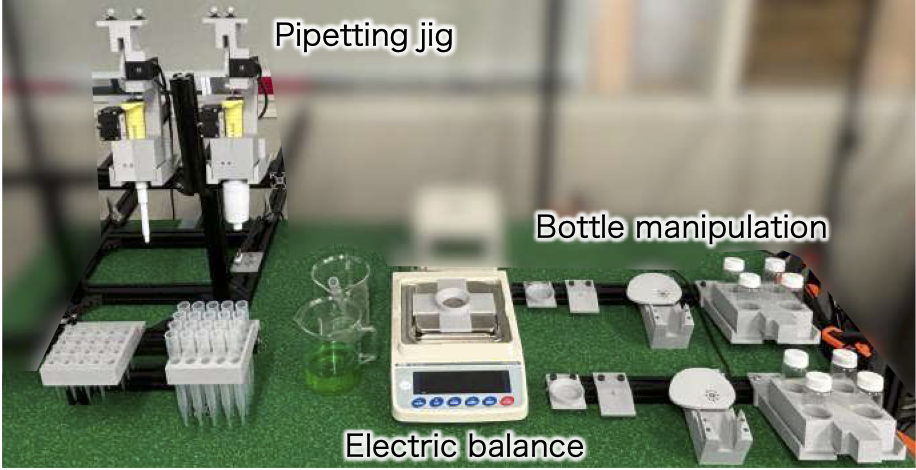

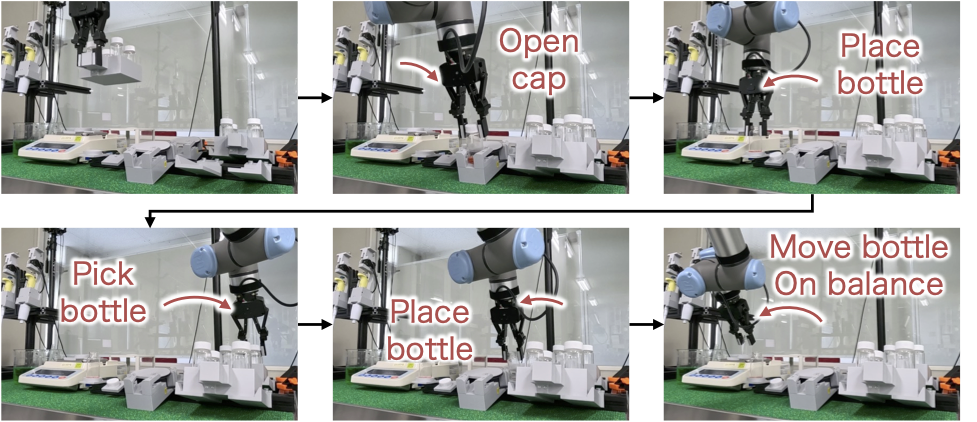

Task 2: Bottle Manipulation for Dilution

At Workspace 2, the robot:

- Places the bottles for dilution

- Opens the lids

- Moves bottles onto the balance for precise pipetting

Bottle manipulation task for dilution setup.

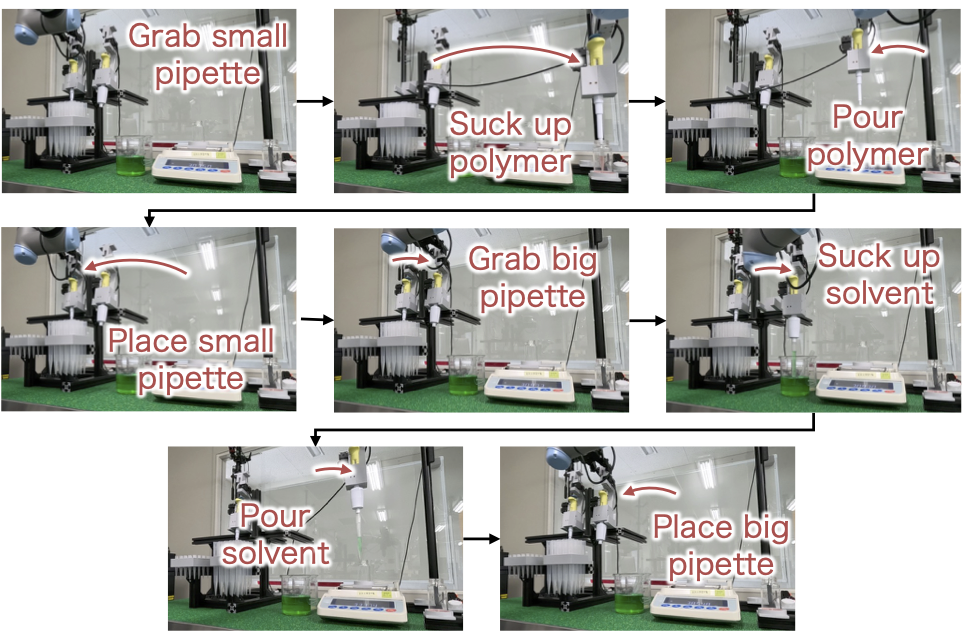

Task 3: Pipetting for Dilution

At Workspace 3, the robot:

- Picks up small and large pipettes

- Aspirates and dispenses polymer and solvent

- Returns pipettes and closes bottle lids

Summary of Results

Full movie of the robot experiment

- 100% task success rate over all trials

- High reproducibility of human-demonstrated motions

- Accurate pipetting volumes, with low deviation from targets

This system shows that complex chemical procedures can be automated without manual programming, making robotic lab automation more accessible to chemists without robotics expertise.

Additional Movies

Pipetting task

Human demonstration (4x speed)

Robot execution (4x speed)

Bottle manipulation task

Human demonstration (4x speed)

Robot execution (4x speed)

Experiment execution by robot (4x speed)

Open-Source Resources

To promote reproducibility and facilitate future research, we provide open-source implementations of both the hardware designs and software components used in our system.

Software

GitHub Repository – Robot Automation System

Hardware Design

We provide 3D CAD files and mechanical design specifications for all jigs.

All parts were designed using Fusion 360 and printed with a FLASHFORGE Creator3 Pro using PLA filament.